At Ispasen Remedies Private Limited, we pride ourselves on our cutting-edge manufacturing and processing facilities designed to ensure the highest quality of our agricultural products. With state-of-the-art equipment and stringent quality control measures, we maintain the standards that make us a trusted global exporter.

Warehouse

The activities are backed by expansive warehousing facilities of 9000 sqft area with a total storage capacity of 66000 bags i.e. 5000 tons Psyllium seeds. The warehouses has facility of material air lock for raw materials. These buildings have cement R.C.C. roof, buffer doors and double (glass & mosquito screen) window.

The warehouses has facility of material air lock for raw materials. These buildings have cement R.C.C. roof, buffer doors and double (glass & mosquito screen) window.

Psyllium Manufacturing Unit

Ispasen Remedies Private Limited is one of the leading manufacturer of Psyllium Husk (Ispaghula Husk) and its base products. It has total Psyllium Husk production capacity around 1900 Tons per annum. There is policy of the company to upgrade the equipments to get the best quality product thus today company stand at the first rank in 100 % customer satisfaction on quality, on time delivery and prompt in communication.

Cleaning of Psyllium Seed

Psyllium Seeds is pass through different types of sieves, aspiration system, Forsberg m ade air classifier, gravity separator, Destoner and Kice make aspirator all this equipments are closed and fully automatic so there is no chance of human contamination.

Grinding of Psyllium Seed

Cleaned Psyllium Seeds is feed into closed automatic grinders which is one of its kind in whole industry. These equipments automatically grind the seeds and separate Husk, powder and cattle feed from the seed without any manual intervention.

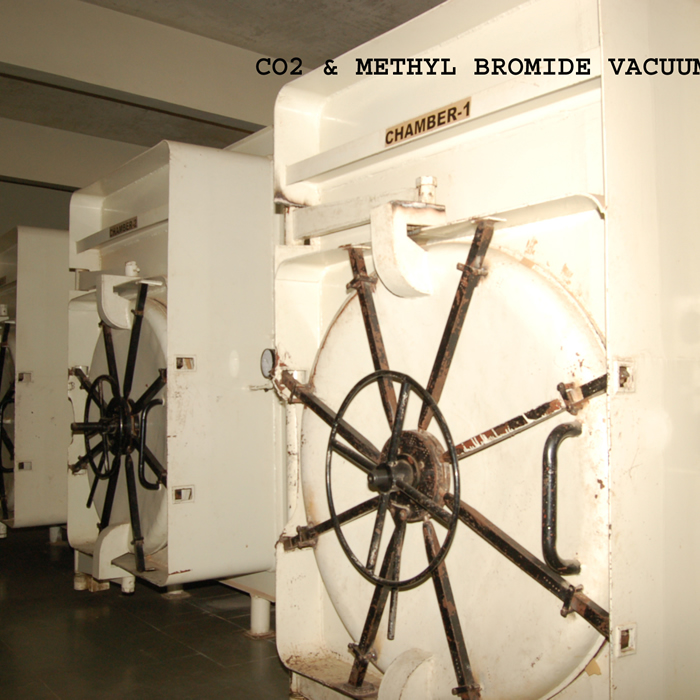

Fumigation Chamber

Finish material Psyllium Husk is fumigated in vaccum chamber for effective fumigation and this will help to reduce the residue problem upto certain extent

Loader Machine

We have our own Forklifts to maintain hygienic condition for handing/loading of finish products in Jumbo Bag. All shipments are made in marine containers which are cleaned and fumigated before stuffing at plant by a specially trained staff